Clinch River Railroad

CRRR - Design of Northern Subdivision

- Details

- Kategorie: Clinch River Railroad

- Zuletzt aktualisiert: Dienstag, 27. Dezember 2016 20:55

- Geschrieben von Michael Homberg

CRRR - Design of the Northern Subdivision

Status of design: 2016-Dec-26

"Clinch River Rail Road", or CRRR, is a freelanced model railroad, designed by Phil Brooks. It is modeled to look and work like the prototype railroads in the Appalachian coal fields in the '50s. An overview of CRRR is here.

End of 2016, when Phil and I prepared operation sessions for the CRRR, Phil for his "Southern Subdivison", and I for Speers Ferry and the "Northern Subdivision", I recognised that I had no clear picture of the trains needed, and the amount and specifics of freight movement.

The good news for this operations planning was: As CRRR was designed as a Railroad Model, which is set in place (see map) and time (1954) and context (the "Real Railroads" as interchanges around CRRR), the basics were set, and were realistic.

My starting points were:

- Phil's layout (set up in Knoxville, Tennessee, US). And the information about his ops planning, with status of end of 2016. Including the trains he planned for the ops sessions.

- the CRRR trackage, which I had mapped in Google My Maps

- my layout of CRRR Speers Ferry Interchange (set up in Weidenberg, Bavaria, Germany)

- the books about Interstate Railroad, by Ed Wolfe. These books are relevant because these describe a "real" railroad which was working in the same time span, and was an Appalachain Coal Hauler, also.

Phil and I discussed the amount of traffic from Big Creek to Speers Ferry, and back. Prototypical operation of coal mines, tipples and loades is one aspect, the amount of traffic our CRRR can handle an other. Some elements had to be compressed. For example I had to lower the number of cars which could be transported.

One factor is the number of cars loaded with raw coal, which will be loaded at the northern branches "Robinette Branch" and "North Fork Branch". These cars will be transported for cleaning and classifying to "Consolidated Coal Preparation Plant" in Yewell via Big Creek, and than back to Big Creek for weighing, and after that beeing transported to the recipients via the staging yards. Teh result of our dicussion was: a good starting point is one northbound and one southbound train per day, = 24 cars/day.

To come to close as possible to get a realistic "Railroad Model", these were the first steps:

- placing the coal loaders into Google My Maps. Giving names to the coal loaders.

- How many cars does one loader load per day? As I did not want to guess only, I took the book "Appalachian Coal Hauler: Interstate Railroad" by Ed Wolfe (2001), looked at the track plans and loading information about the tippes and loader, and chose one "real" loader as a prototype for every one of the loaders on CRRR Northern Subdivision. Some of these prototypes are described below.

Glad to come so close to the real world, I summed up the coal traffic at Northern Subdivision.

The first addition of coal cars showed: much to much. Therefore, I closed four loader and tipples.

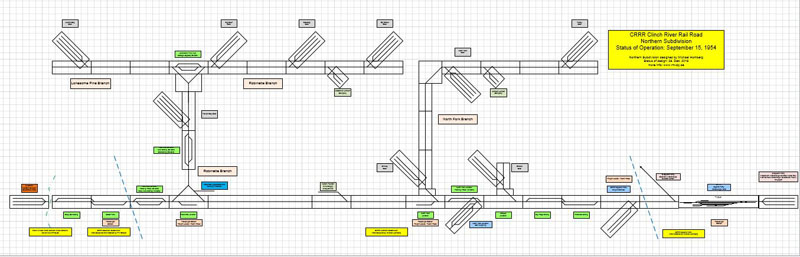

CRRR Northern Subdivision: schematic track plan, without the closed coal loaders. Here is pdf for larger image

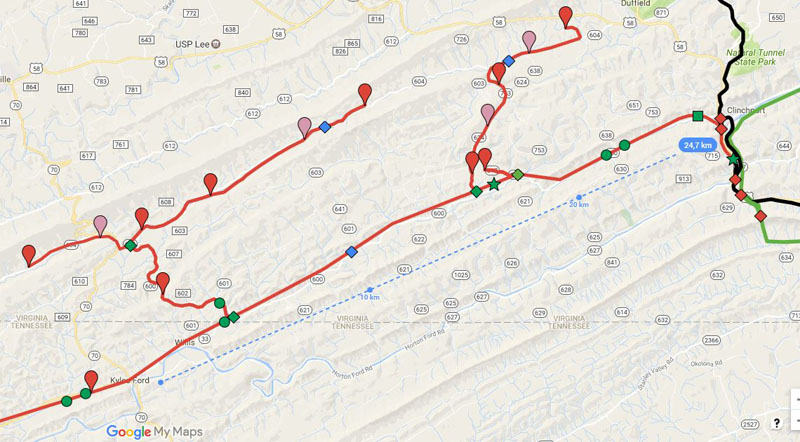

The same area, in Google my Maps. Note: the pink balloons show the four closed coal loaders.

But, there were (summed up: raw coal + classified coal) still more than 200 coal cars per day, as MTY = Empties towards the loaders and tipples, and the same number back. Still to much.

Step by step I reduced the number of cars each of the remaining tipples and loades is shipping per day.

The result is:

- 24 cars of raw coal (see above: the upper limit)

- 72 cars of classified coal. This coal is cleaned at the tipples, and sorted and loaded as 3 different grades.

At this phase of planning, the CRRR had only one place for weighing of coal cars, and this was Big Creek. Therefore, all coal cars had to be routed via Big Creek. This would have been to much traffic on the Main Line, and to much work for one place to weigh.

Looking at the Interstate books, I found out that Interstate had a second weighing place, at Norton. Following the prototype, I set up a weighing place at "North Fork Junction Car Weighing". Doing this, I reduced the Main Line traffic by about 144 cars/day = 6 trains/day.

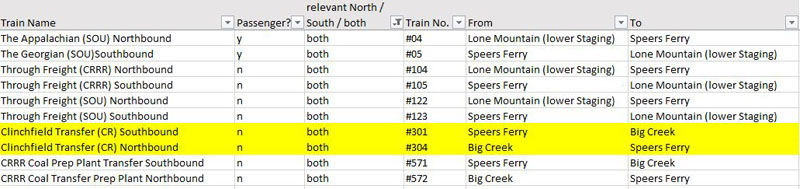

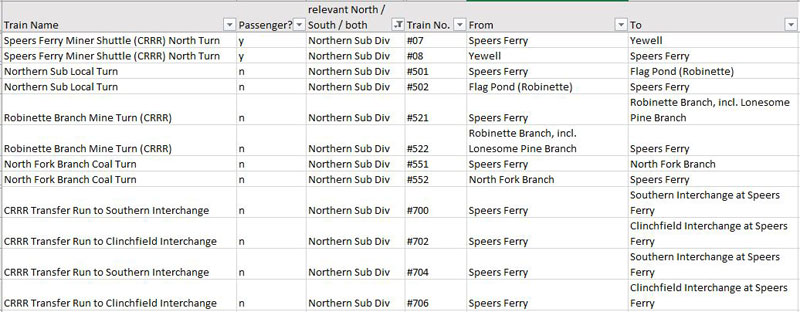

As a result, these are the trains that will be operating (planning status: 2016-Dec-26):

Trains moving across CRRR network = Southerrn and Northern Subdivision

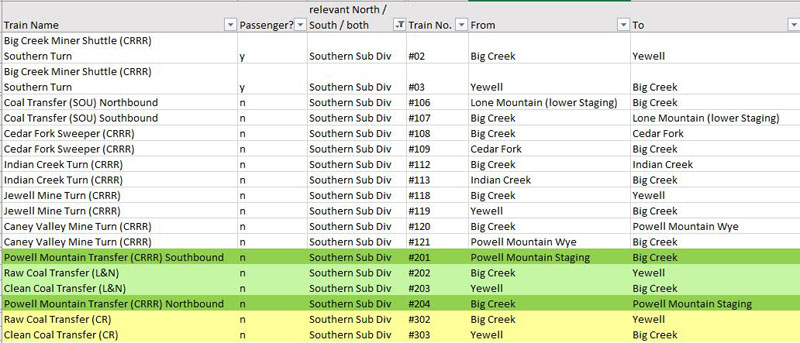

CRRR Trains in Southern Subdivision

CRRR Trains in Northern Subdivision

Coal Tippes and Loaders at CRRR Northern Subdivision

Number of coal cars transported on CRRR Northern Subdivision, and the numer of cars at the prototype, the Interstate RR.

For the details of the LDE please look at the following:

Prototypes of CRRR Coal Tipples and Loaders

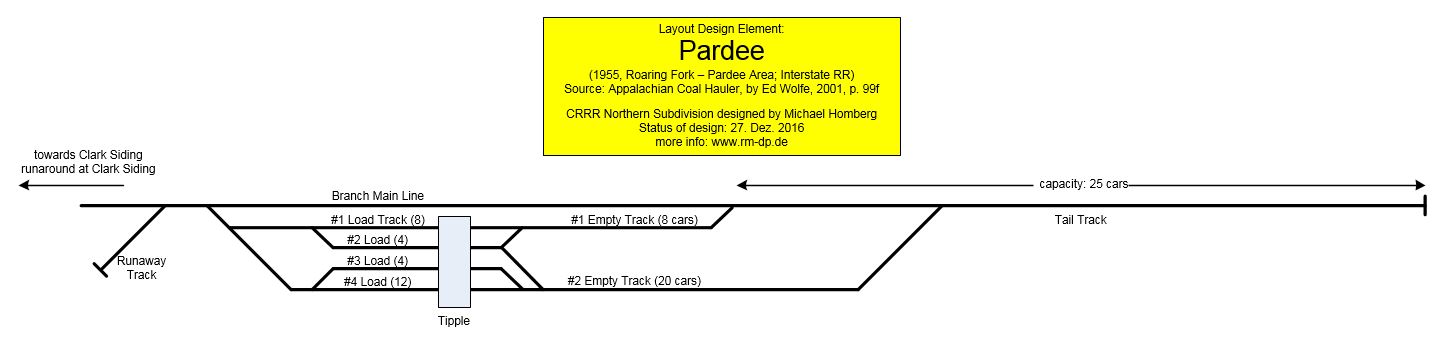

Pardee

Pardee is the LDE (= Layout Design Element) for "Fraley Coal", at CRRR North Fork branch, and "Dry Creek Coal" at CRRR Robinette Branch.

Pardee loaded about 25 to 30 cars per day, classified to several coal grades.

The loading area was on a steep grade, therefore a Runaway Track was installed. And no switcher was needed to move the cars at the tipple, the gravity gave enough power.

Pardee Tipple, Roaring Fork - Pardee Area, north of Kent Junction, Interstate RR (click here for larger pdf)

Data Source: Appalachian Coal Hauler, by Ed Wolfe, 2001, p. 99f

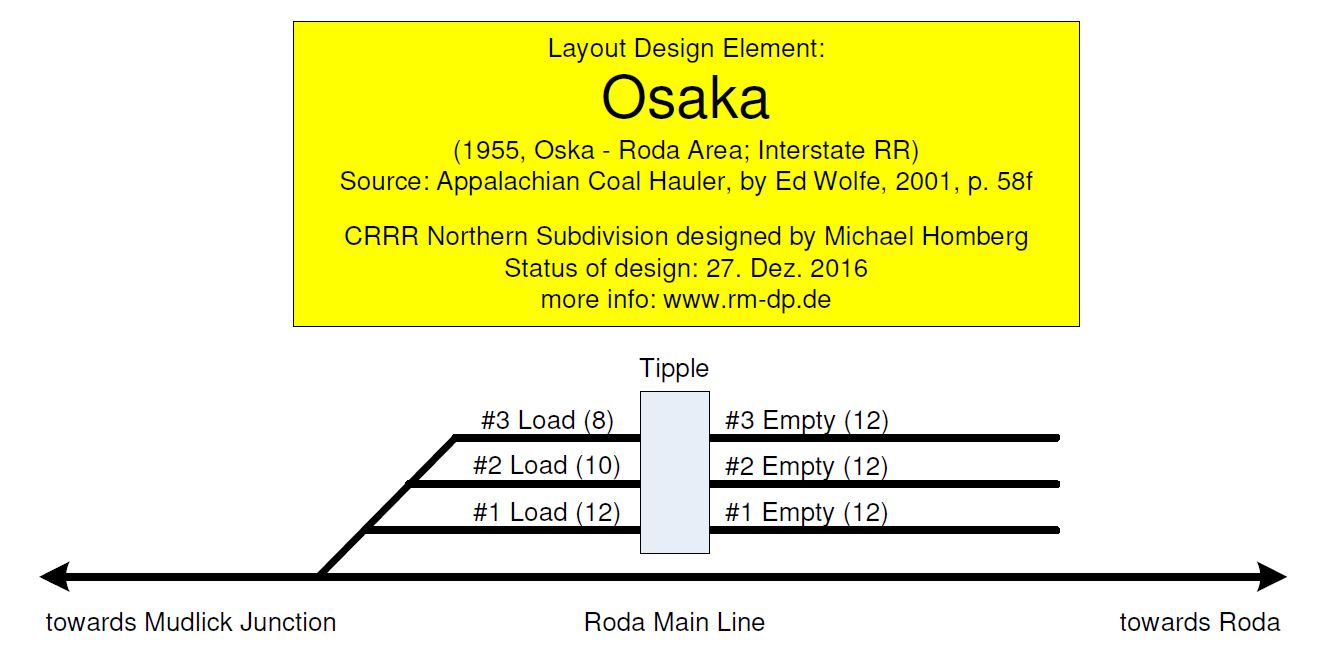

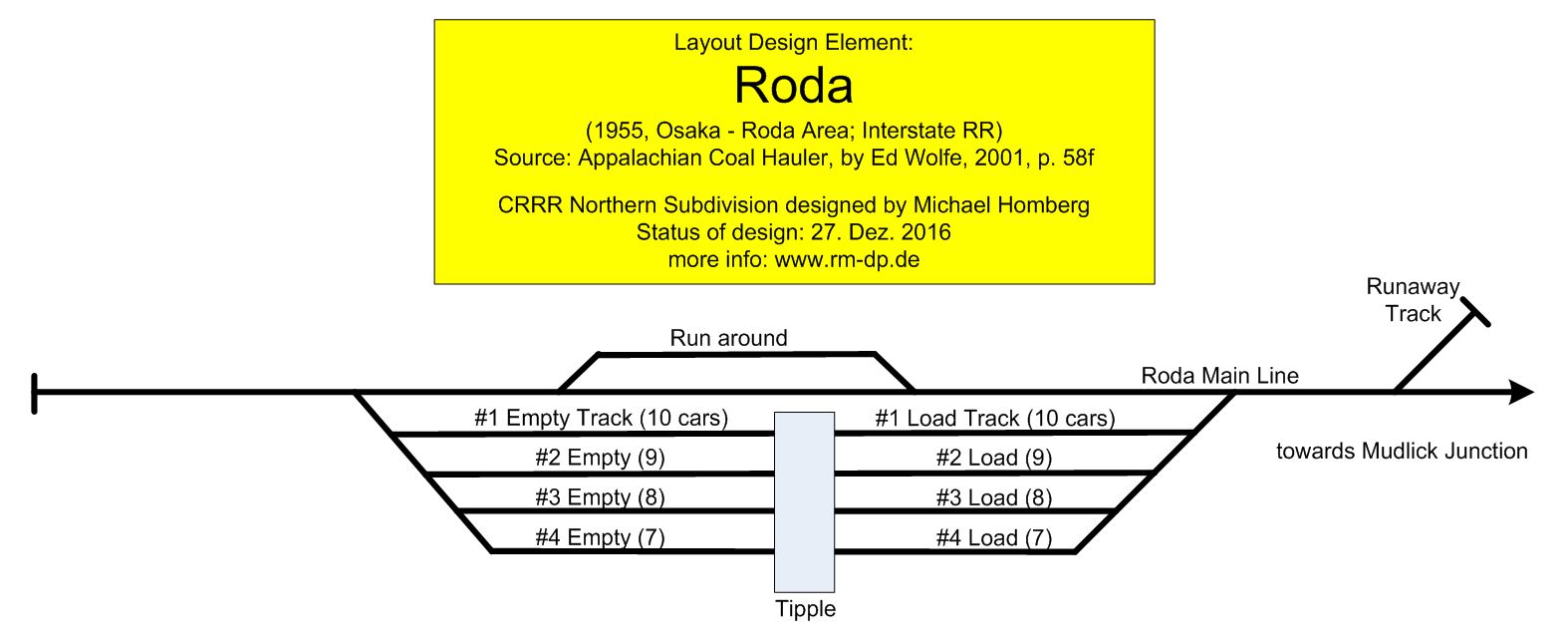

Osaka

Osaka is the LDE for "North Fork Coal", at CRRR North Fork branch.

Osaka loaded about 25 to 30 cars per day, classified to several coal grades.

Osaka Tipple, Osaka - Roda Area, north of Mudlick Junction, Interstate RR

Data Source: Appalachian Coal Hauler, by Ed Wolfe, 2001, p. 58f

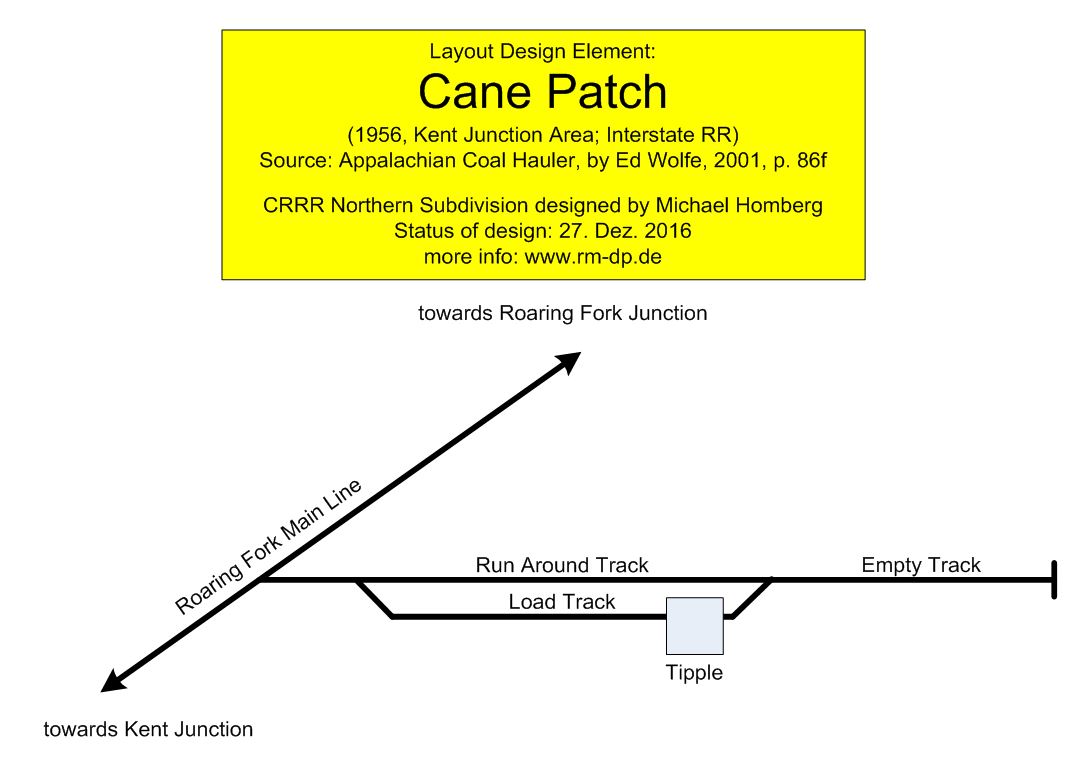

Cane Patch

Cane Patch is the LDE for "Dinsley Coal" and "Drakes Coal" at CRRR North Fork branch, and "Flower Gap Coal" at CRRR Robinette Branch.

Cane patch loaded raw coal (= not preparated = not washed, not classified).

When starting operations, it loaded about 8 to 12 cars per day, and in late 1990s, about 30 - 35 cars per day.

Cane Patch, Kent Junction Area, north of Kent Junction, Interstate RR

Data Source: Appalachian Coal Hauler, by Ed Wolfe, 2001, p. 86f

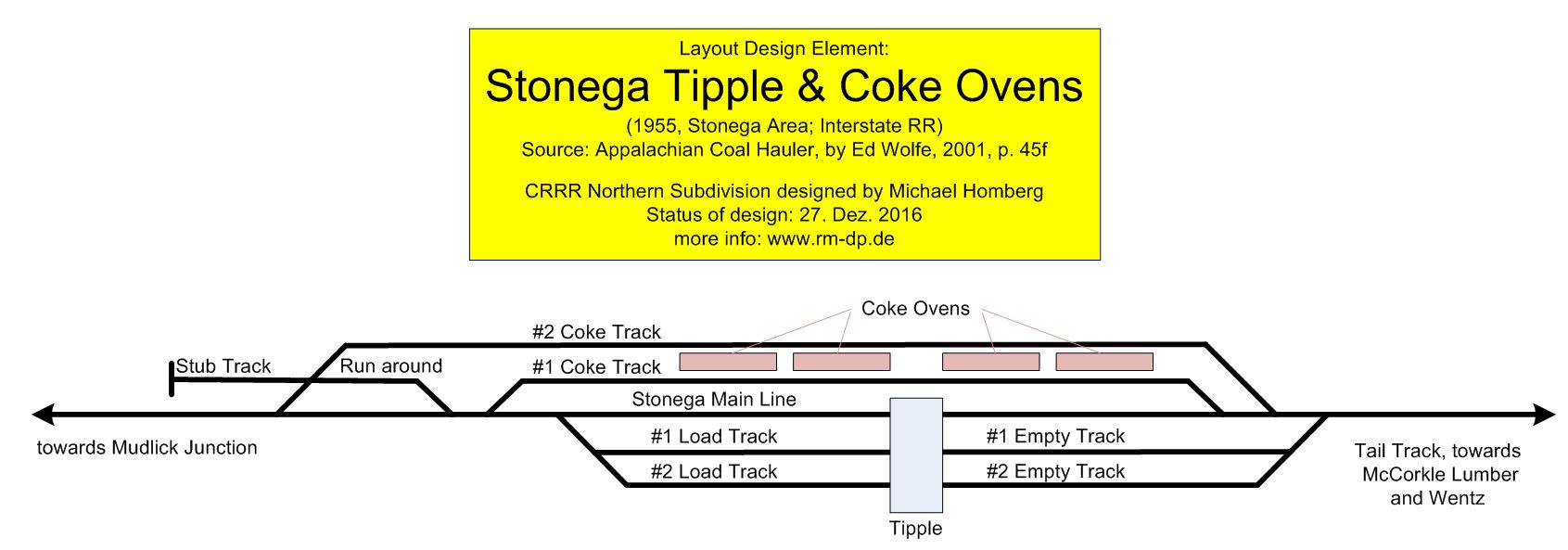

Stonega

Stonega is the LDE for "Blacktop Coal", at CRRR Robinette branch.

Stonega loaded about 25 to 30 cars of coal per day, classified to several coal grades.

At its peak, Stonega made 40 to 50 cars a day, in sum of coal and coke.

Stonega Tippe & Coke Ovens, Stonega Area, north of Kent Junction, Interstate RR

Data Source: Appalachian Coal Hauler, by Ed Wolfe, 2001, p. 45f

Note: the Coke Ovens were operated until 1953. Therefore, in 1955 the coke oven tracks could be used for non-coke traffic.

Band Mill

Band Mill is the LDE for "Big Door Coal" at CRRR Robinette Branch.

Band Mill loaded raw coal, about 20 cars per day.

Band Mill, Roaring Fork - Pardee Area, north of Kent Junction, Interstate RR

Data Source: Appalachian Coal Hauler, by Ed Wolfe, 2001, p. 104f

Roda

Roda is the LDE for "Blacktop Coal", at CRRR Robinette branch.

Roda loaded about 50 cars of coal per day, classified to several coal grades. Night train crew and day train crew were working at Roda, each with 25 cars.

Roda, Oska - Roda Area, north of Kent Junction, Interstate RR

Data Source: Appalachian Coal Hauler, by Ed Wolfe, 2001, p. 158f