Industry Spurs

Collaboration of large Industries and Industry Support Yards

- Details

- Kategorie: Industry Spurs

- Zuletzt aktualisiert: Freitag, 05. März 2010 14:23

- Geschrieben von Michael Homberg

Industry Spurs: how to coordinate Large Industries, Industry Support Yards and major Classification Yards

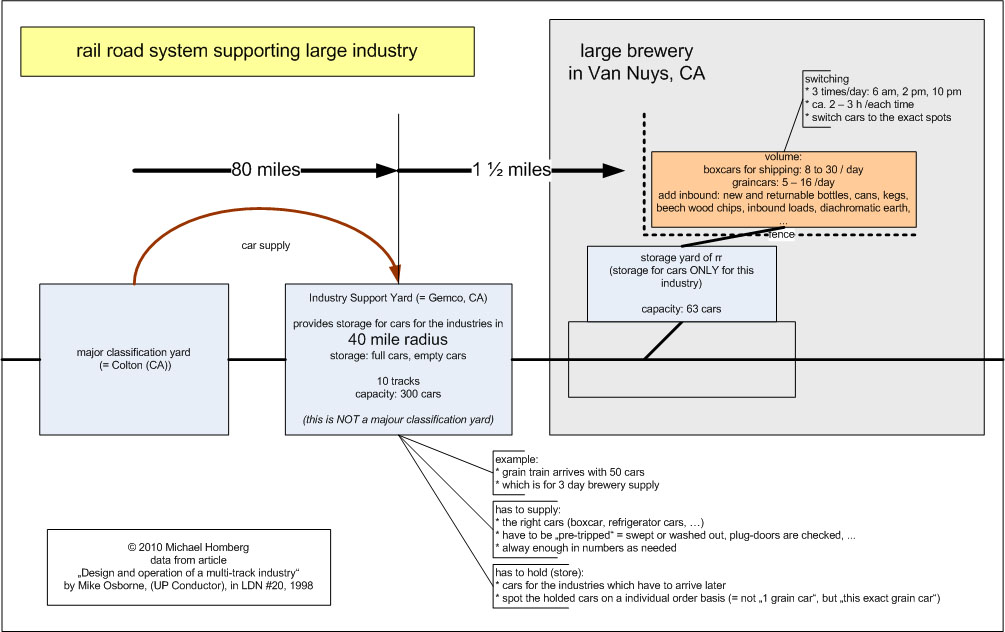

LDN "Layout Design News" #20 of summer 1998 published the article "Design and operation of a major multi-track industry - A Brewery as a Layout Design Element".

Author Mike Osborne is Conductor of the Union Pacific. With the eyes of the insider, he describes the flow of cars from the far away big Classification Yard Colton, CA, the intermediate Industry Support Yard Gemco, CA, towards the big brewery in Van Nuys, CA:

This system offers a lot of operation chances, and it will be a little bit tricky to operate smoothly. One of the big challenges may be the available space, especially in Germany where I am living. On the other hand, I am operating in the americaN module group, and here we have "unlimited" space when we meet two times a year.

To operate the industry layout in a prototypical manner, two components have to match:

- the layout of the industry tracks, including the storage yard outside the brewery fence

- the collaboration with the Industry Support Yard

What are the tasks of these three components?

Major Classification Yard:

This is the important connection point to the whole railroad system.

Here, the main tasks are:

- to always supply the Industry Support Yard with the empty cars needed

- to gather all freights for the brewery from through trains, and to send them to the Industry Support Yard

Industry Support Yard:

This yard has to support the industries in a radius of about 40 miles. This specific yard is called Gemco Yard, and it got its name because it is directly besides a General Motors factory.

Gemco Yard supports about 100 industries, and a few of them need as many cars as the brewery or General Motors. Most industries are a lot smaller, and some may need a car or two per month.

The main task of Gemco Yard is to store full cars as long as the consignee wants to. And the second is to hold a supply of enough empty cars and to bring them to the customer as needed.

Mike Osborne writes: "Modeling a yard in this scale is much more practical [add. MH: than a classification yard] and I'm sure that, with the proper knowledge of the prototype, modelers could switch to their heart's content".

Here you find the aerial photo of Gemco Yard in Google Maps.

Brewery Yard:

The three storing tracks outside the fence of the brewery are only used for cars for this brewery at Van Nuys, CA. Most of all, they are used to store the full and empty cars while a switching session, which takes about 2 to 3 hours, three times a day.

One of the most important tracks is the switching lead. Please remember: on the other hand, the main track would be occupied by switching for 3 times a day, each for 3 hours. That would be 9 hours a day, and this would not be efficient!

How many cars were switched when this article was published in 1998?

freight outbound:

- 8 to 30 boxcars with bottled beer

- refrigerator cars with beer in kegs

inbound:

- 5 to 16 covered hoppers with malt and rice

- packaging material

- backloads of empty returnable bottles and kegs

- covered hoppers with diatomaceous earth (for filtering)

- boxcars with beech wood chips (for aging of beer); 2 cars per month

- clean empty box cars for shipping of bottled beer

- clean empty reefers for beer in kegs

Here you find the aerial photo of Van Nuys brewery in Google Maps.